A sustainable, innovative new process for carbon fibers could revolutionize several industries that rely on the material, traditionally manufactured using petroleum. A research consortium led by the Technical University of Munich (TUM) in Germany developed the breakthrough method. It reportedly addresses environmental harm from carbon fiber production, an essential material in the aviation, wind energy, and construction industries.

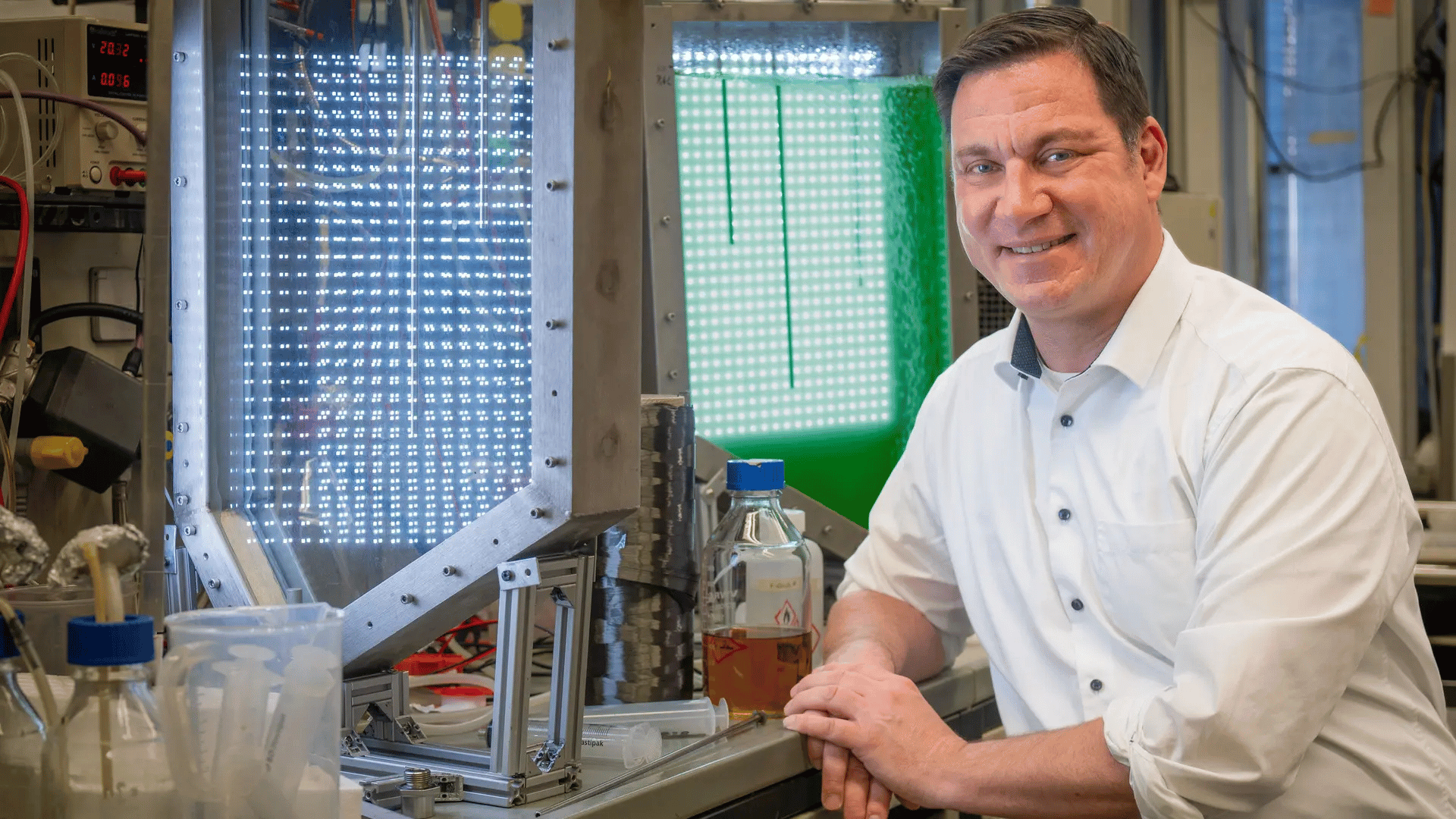

The new process utilizes algae, specifically photosynthetically active microalgae that bind greenhouse gases and produce valuable algae oils.

“Through photosynthesis, microalgae bind the greenhouse gas CO2, among other things, in the form of algae oils,” Thomas Brück of the TUM School of Natural Sciences explained.

Carbon fiber is a popular material in many industries because it is lightweight and durable. However, the material emits significant greenhouse gases into the atmosphere.

A Natural Process in Carbon Fiber Production

According to the research consortium, the next step involves converting the algae oils into glycerine. The Fraunhofer IGB institute developed a process to catalytically convert glycerol into a key raw material for carbon fiber production called acrylonitrile.

Dr. Arne Roth, a department head at Fraunhofer IGB, said, “We have thus created the conditions for the production of sustainable carbon fibers that have the same high-performance properties as conventionally manufactured carbon fibers.” The process is reportedly ready for industrial scaling. If so, it would mark a major step towards commercialization.

SGL Carbon produced the new sustainable carbon fibers. The company created 50,000 heavy-tow carbon fibers, which are exceptionally stable and meet industry standards. Then they were used to manufacture fiber-enforced plastics called composite laminates.

European aerospace group Airbus is also involved in the GreenCarbon project. The company is an associate partner and conducted a life-cycle assessment of the new tech. It is now working on a demonstration of its viability for aircraft. A research helicopter made from these sustainable carbon fibers took its maiden flight in 2024.

While the aircraft proved the materials’ capabilities, the consortium wants to bring it to wider industrial use.

“Our GreenCarbon value chain thus offers new potential for the raw materials transition in the chemical industry,” Brück said.