Tomorrow's World Today

Innovation

Tomorrow's World Today

Innovation

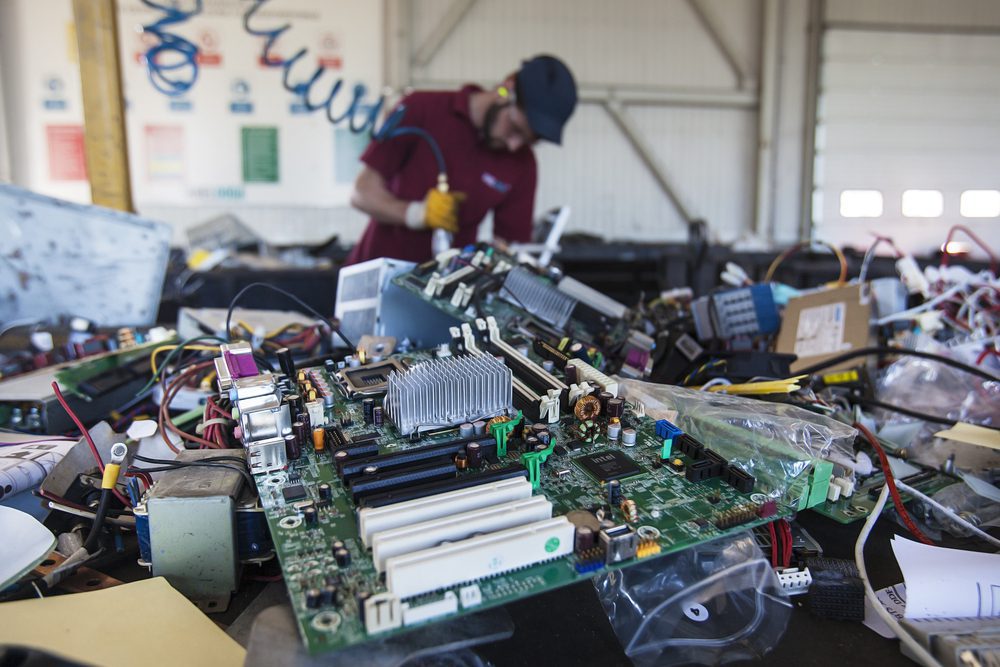

S4E01 – The Science Behind Electronics Recycling

In the World of Innovation, we learn how mining has evolved from the days of the California Gold Rush to harvesting the precious metals found inside our electronic scrap and how electronics recycling helps our environment.

Back to SeasonsKeep Watching

S4E15 – Material Science Meets Building Science

S4E14 – The Tires of Tomorrow

S4E13 – The Science Behind Supplements

S4E12 – Getting Paid to Shop

S4E11 – Nuclear Does What, Now?

S4E10 – Big Power in Small Packages

S4E09 – The Past, Present, and Future of Nuclear Energy

S4E08 – The Clean Factor

S4E07 – Pipe Dreams

S4E06 – Science Behind Relocation

S4E05 – Semiconductors In Space

S4E04 – Empty Driver’s Seat

S4E03 – Innovations in Forestry Management