If you’ve ever used a camera flash or a medical defibrillator, you’ve relied on a capacitor. While batteries are great for the long haul, capacitors are the “sprinters” of the electronics world. They provide the quick bursts of power needed for high-energy tasks.

The catch, however, is that they hate the heat. Most standard polymer capacitors start to fail once they hit 212 degrees Fahrenheit. That’s a major issue for electric vehicle engines or busy data centers that easily get that hot.

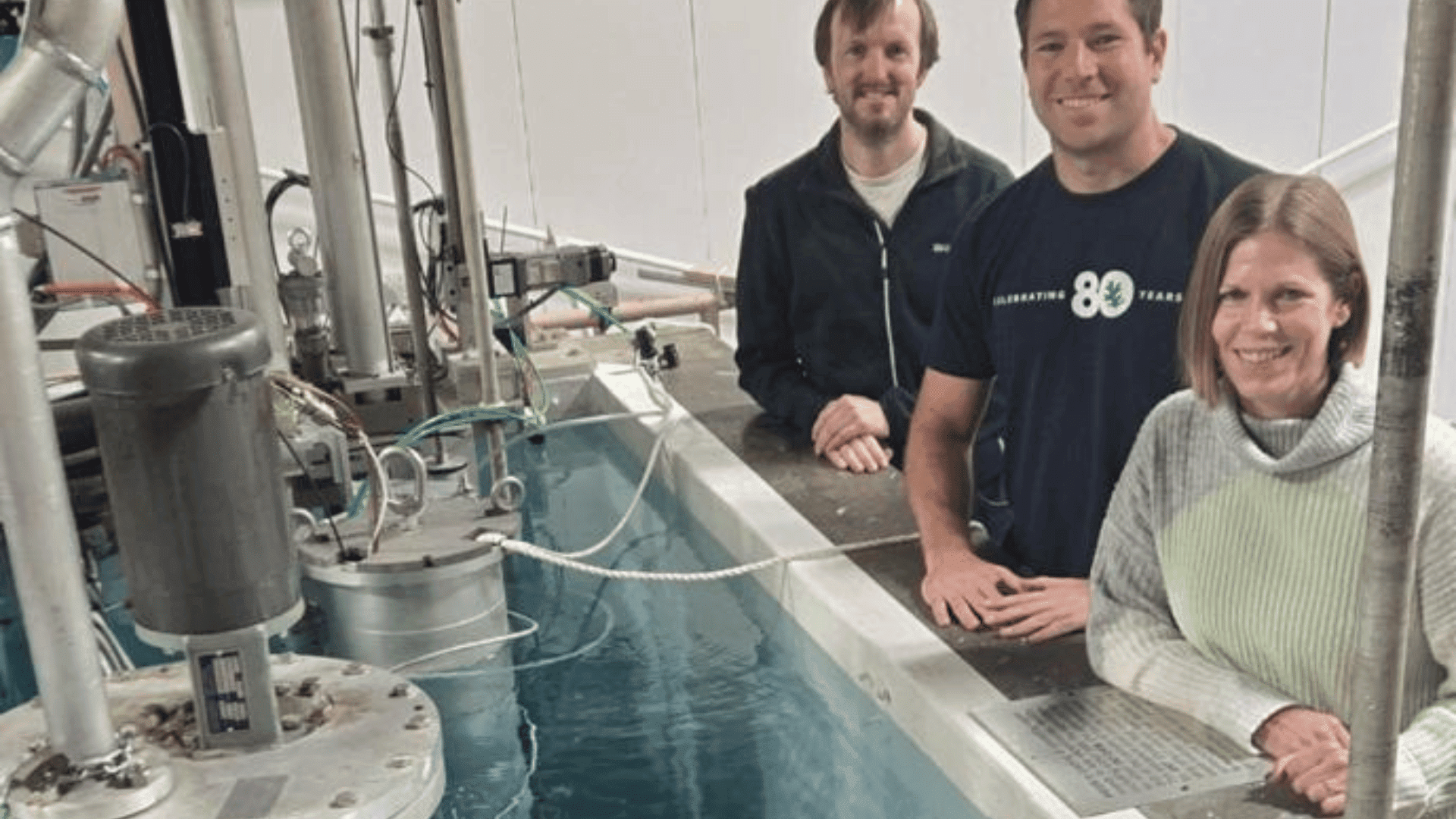

Researchers at Penn State have found a way to fix this using a bit of “kitchen science” with plastic. Mixing two common, store-bought plastics created a material that handles four times the energy of a normal capacitor and stays stable up to a scorching 482 degrees.

“Advances in the full systems for electric vehicles, data centers, space exploration and more can all hindered by the polymer capacitor,” said Li Li, a postdoctoral scholar at Penn State. “Conventional polymer capacitors need to be kept cool to operate.

“Our approach solves that issue while enabling four times the power — or the same amount of power in a device four times smaller,” Li added.

Mixing Oil and Water

The secret isn’t a new chemical, but how two existing ones interact. The team combined a plastic used in medicine (PEI) with a heat-resistant insulator (PBPDA). These two materials don’t like to mix, much like oil and water. Because they resist each other, they naturally organize into tiny 3D structures that act as a shield, stopping electricity from leaking out when things get hot.

“Normally, you can’t have both high energy density and high temperature tolerance in one dielectric polymer — we achieved both by mixing two commercially available high-temperature polymers,” said co-first author Guanchun Rui.

The results even surprised the researchers. On their own, these plastics aren’t very powerful. However, when joined together, their energy storage capacity, known as the K value, jumped from less than 4 to 13.5.

“The dielectrics are cheap and commercially available, the process to make large quantities is simple,” Li said. “This is a cost-effective solution to [the] energy crisis and could significantly help across multiple applications.”

“We can put four times the power into a device, or shrink a device to one-fourth its size while it keeps the original amount of power,” Li added. “We can put a lot of function into something very compact in easily achievable way.”