Engineers expect next-generation nuclear reactors to run much hotter than the ones we currently have. High heat is a big upside for efficiency, but it’s challenging to develop the technology for it. Mainly, the sensors that monitor the reactor must be tough enough to stay accurate and withstand the extreme temperatures.

A team at Oak Ridge National Laboratory (ORNL) is testing a new prototype to see if it could handle the intense heat. The device is a high-temperature fission chamber. Essentially, it’s a sensor that detects neutrons. Sensors are vital to the reactor because they tell the operators how much power the reactor is generating to help start the system safely.

Testing at 800 Degrees

Advertisement

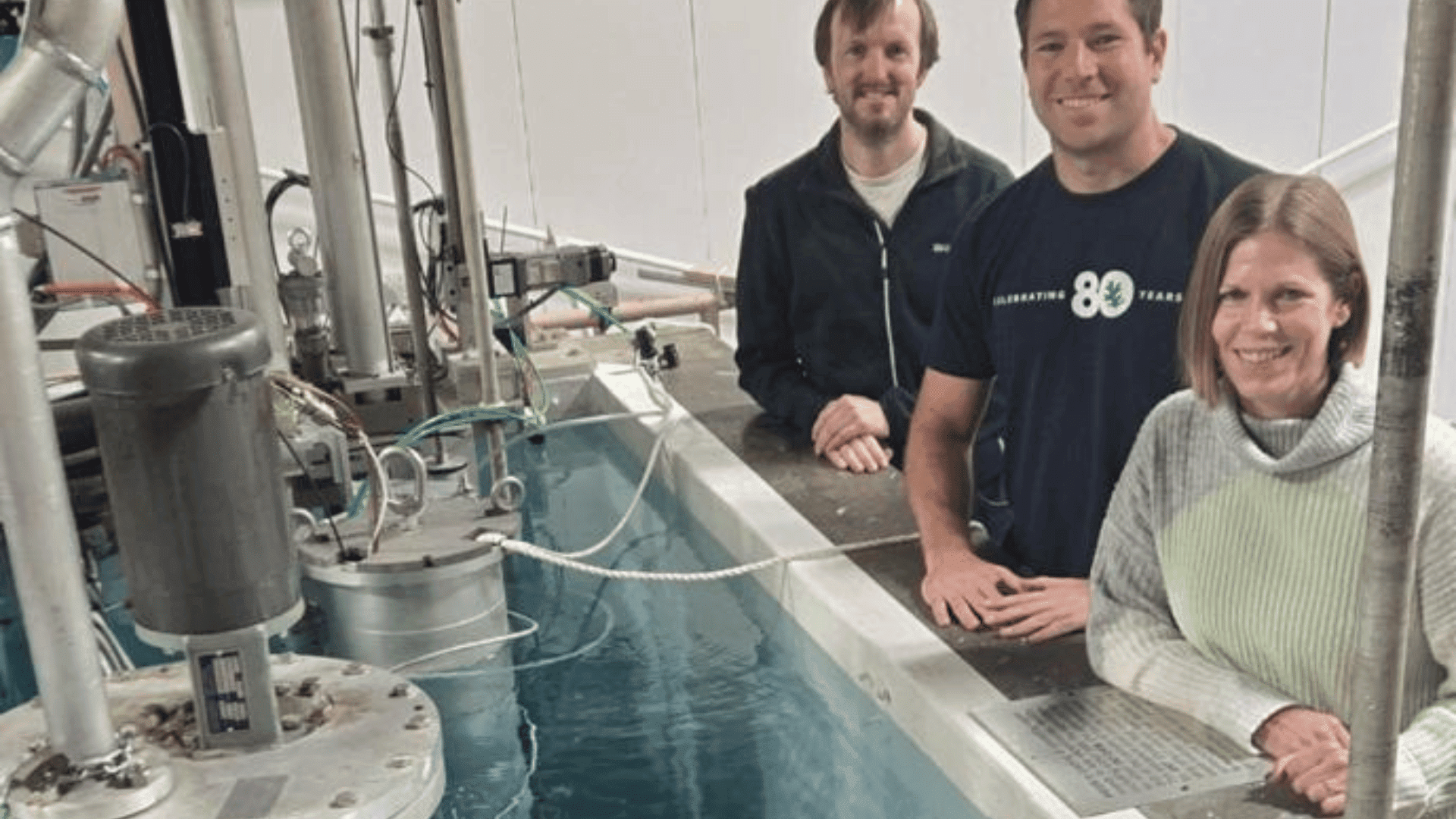

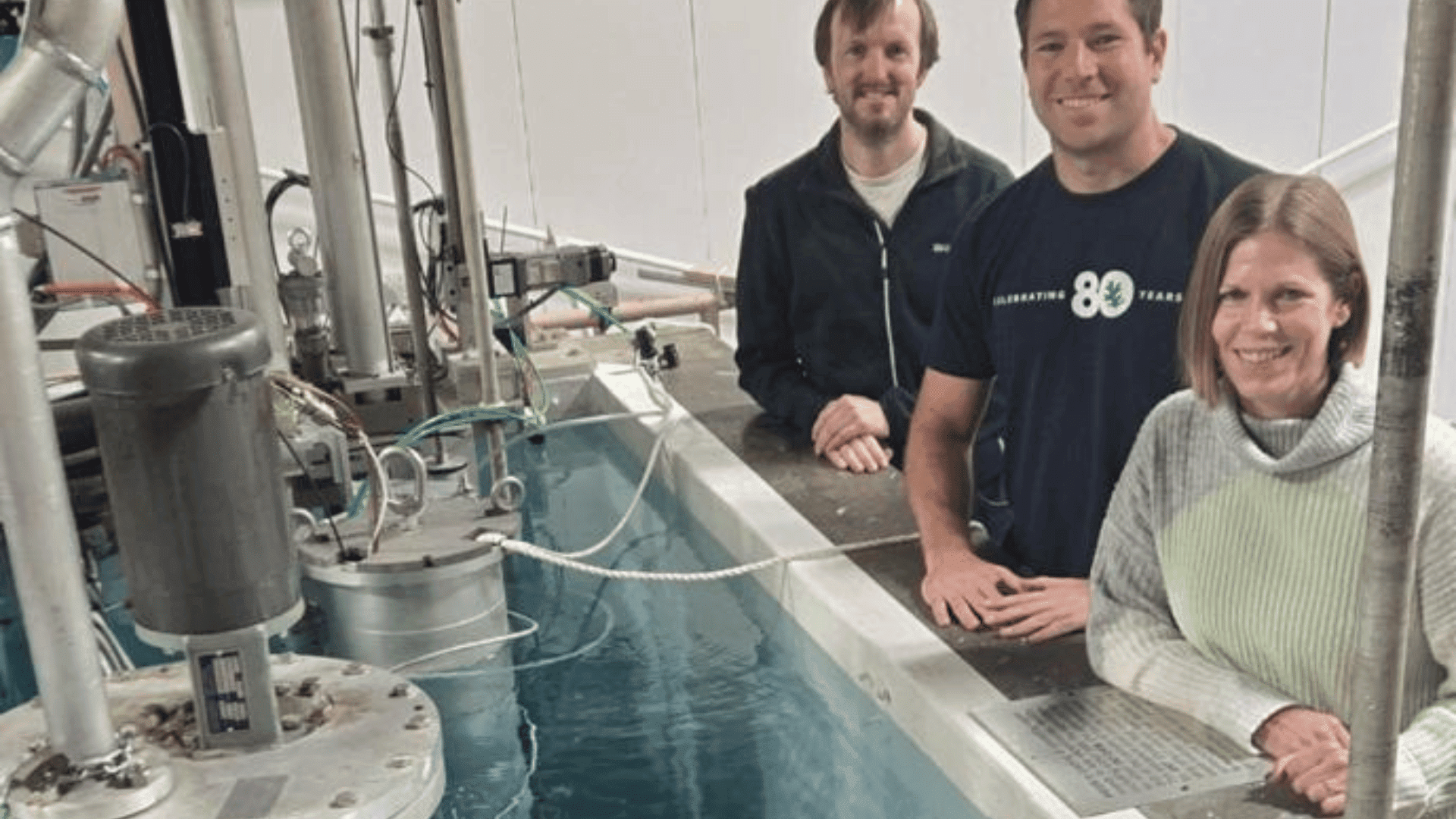

The prototype was designed by the equipment manufacturer Curtiss-Wright, but they needed ORNL’s help to simulate the harsh conditions of a modern reactor. The lab built a custom testing rig and took the sensor to The Ohio State University Research Reactor for a week of intense evaluation.

During the test, the sensor had to work while being blasted with radiation at temperatures reaching 800 degrees Celsius, hot enough to melt some types of glass. Even at those extremes, the sensor didn’t flinch. According to the researchers, it kept delivering steady data across all power levels. This test proved that it could survive the maximum heat range expected in advanced reactor designs.

“Designing experiments that push these crucial sensors to their limits is something ORNL is uniquely equipped to do,” said Brandon Wilson, an R&D staff member at ORNL. “Our expertise in recreating extreme environments is exactly why partners come to us when they need confidence in how a new component will perform.”

For researchers to develop advanced, next-gen reactors, they first have to develop strong components that allow them to operate. This recent success helps engineers push toward reliable, clean, and powerful energy.