For the first time in half a century, a brand-new aluminum smelter is coming to the United States. Century Aluminum and Emirates Global Aluminium (EGA) announced a partnership to build a massive facility in Inola, Oklahoma. This move is expected to more than double the country’s current production of primary aluminum.

Additionally, the project is important for the local economy. It’s projected to create over 1,000 permanent jobs, plus another 4,000 jobs while the site is being built. Once it’s up and running, the smelter should churn out about 750,000 tonnes of aluminum every year.

Aluminum Smelter

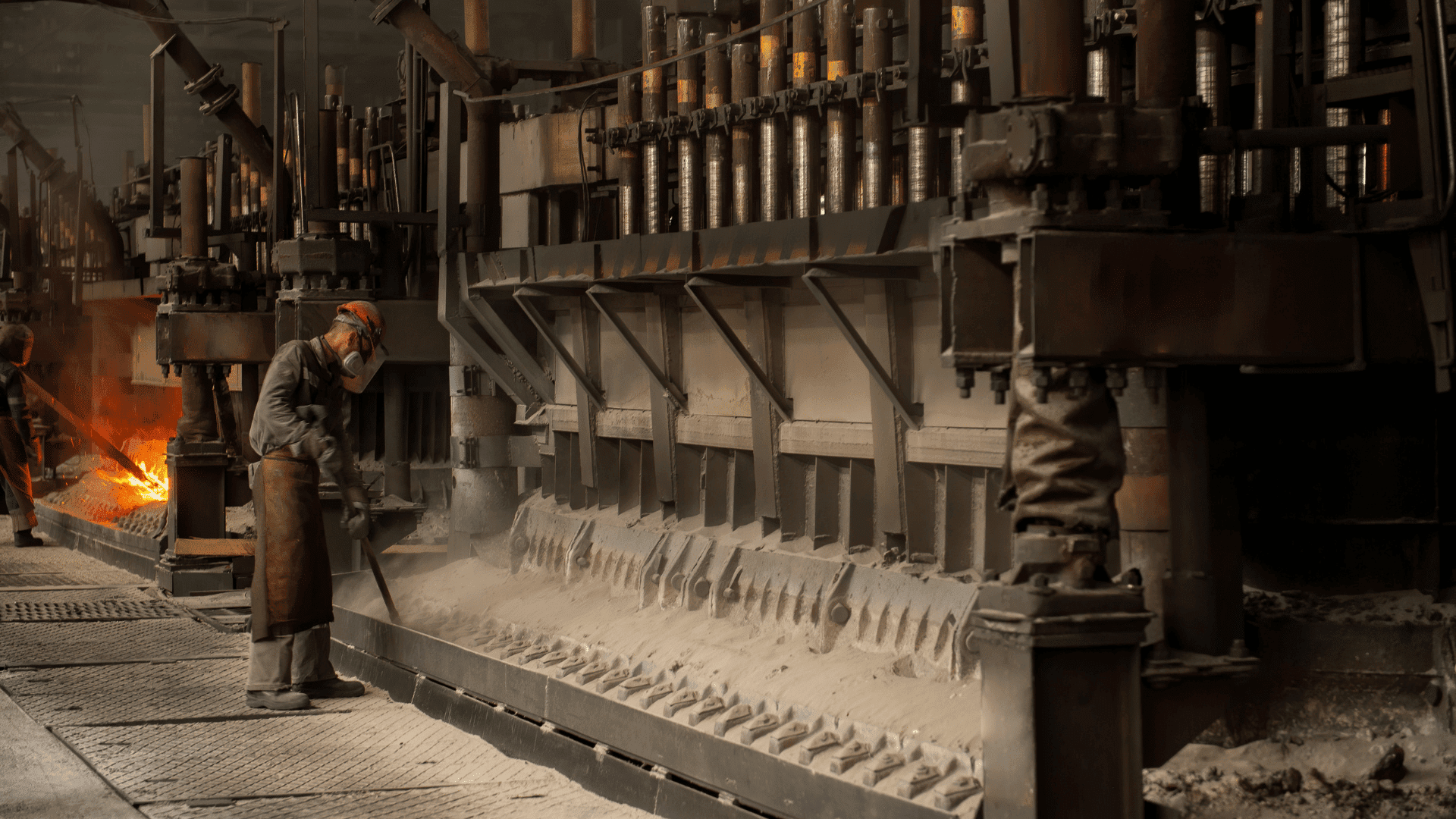

An aluminum smelter is essentially a large industrial plant where raw materials are turned into pure aluminum metal. It’s the middle step of the process because you don’t just dig aluminum out of the ground like gold. Instead, you mine a rock called bauxite, refine it into a white powder called alumina, and then send that powder to the smelter.

Inside the smelter, the alumina powder is dissolved in a “bath” of molten minerals. Because aluminum is very stable, you can’t just melt it down with a flame. You have to use a massive amount of electricity to “break” the chemical bonds holding the aluminum and oxygen together.

Building for the Future

The American Primary Aluminum Association (APAA) is backing the move, pointing to recent trade policies as the main reason this is happening now. They believe the 50% tariff on aluminum imports provided the necessary spark to make domestic production viable again.

“This partnership between Century Aluminum and EGA is the biggest step yet toward making the nation’s largest smelter featuring the world’s most advanced smelting technology a reality,” said Mark Duffy, the President of the APAA.

The engineering work has already started. If everything stays on track, construction should begin by the end of 2026. While the U.S. has relied heavily on imports for decades, this new facility in Oklahoma suggests the tide is starting to turn for home-grown manufacturing.