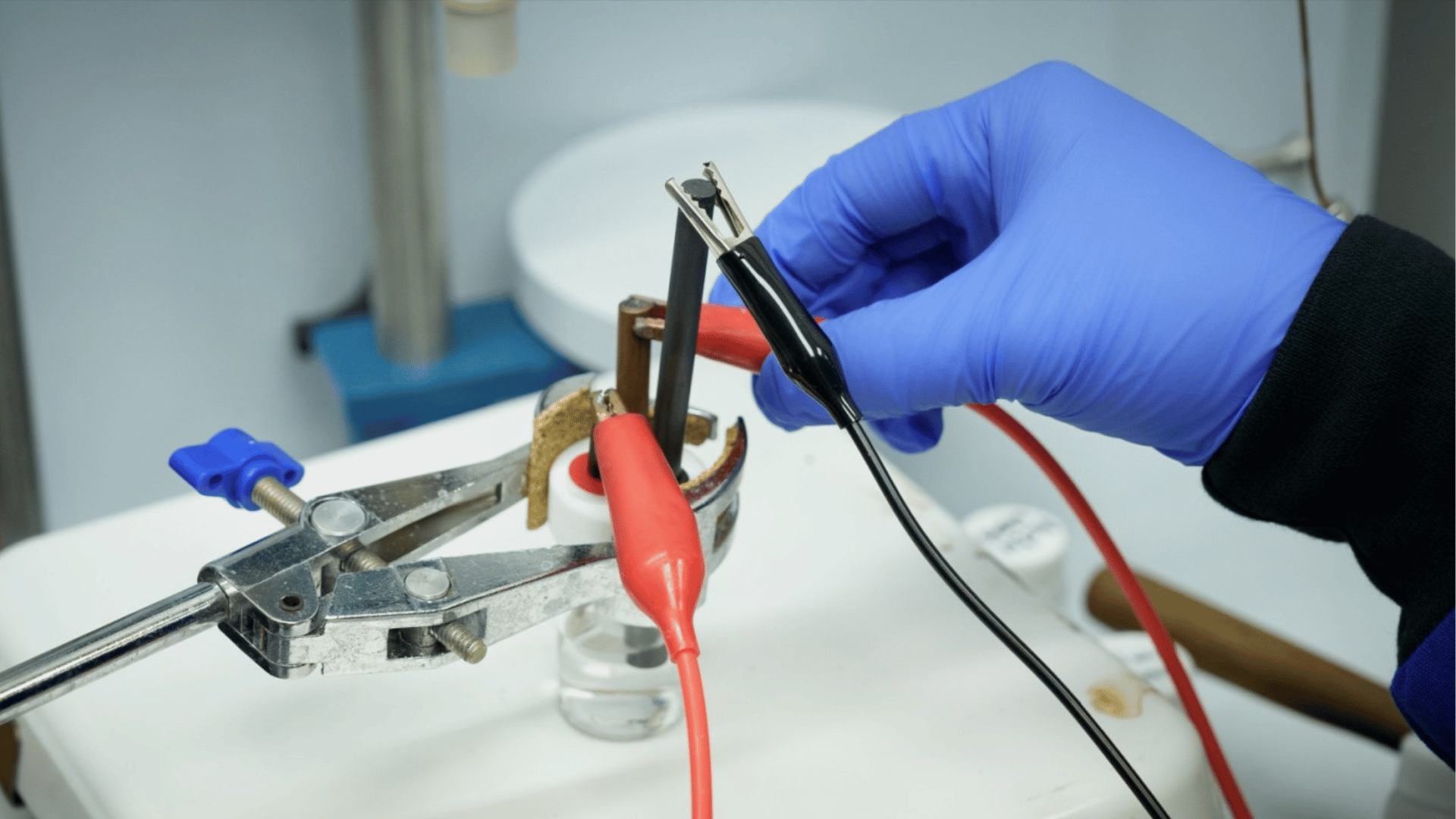

Construction production is all about the numbers. How fast can you move? How accurate is the work? And how much does it cost to fix mistakes? DEWALT, working with August Robotics, just announced a new tool that hits those metrics hard.

They are launching the world’s first downward drilling robot. It’s fleet-capable, meaning you can have multiple units working together to ramp up output. This is a big deal for data center construction, where the pressure to build fast is incredibly high.

Boosting Construction Output

The production stats coming out of the pilot program are impressive. This robot has already completed 10 phases of construction with one of the world’s largest tech companies. During that time, it drilled over 90,000 holes.

Aside from the sheer volume, it’s also about precision. For example, the robot delivered 99.97 percent accuracy for both location and depth. In the world of concrete drilling, that level of consistency drives cost-efficiency by radically decreasing the cost per hole. You aren’t wasting time re-drilling or fixing errors.

The speed is also a major factor. The robot drills up to 10 times faster than traditional methods. In the pilot alone, this shaved 80 weeks off construction timelines.

“Across the globe, hyperscalers, which account for nearly 80% of overall data center demand, are investing in infrastructure to power AI computing, with an estimated industry-wide capital expenditure of $7 trillion in data centers by 2030,” Bill Beck, President of Tools & Outdoor at Stanley Black & Decker, said. “Our customers consistently emphasize that speed of construction is critical.

The robotic drilling solution meets this need head-on through schedule acceleration, cost savings, near-perfect accuracy and enhanced jobsite safety. DEWALT’s relentless pursuit of innovation to drive productivity is redefining how the world builds.”

Fixing the Workflow

Drilling holes might sound simple, but at this scale, it is a crucial stage of the workflow. These robots are drilling thousands of holes to install server rack stops and the structural legs that support overhead mechanical, electrical, and plumbing systems. If this step lags, everything else waits.

By automating this, the robot unlocks greater drilling capacity. It also fits into DEWALT’s wider ecosystem of “Perform and Protect” tools, which helps mitigate dust and vibration—keeping the production environment safer for human workers nearby.

If you want to see how this fits into a live production line, the robot will be demoed at the World of Concrete Trade Show in Las Vegas. It is expected to be commercially available in mid-2026.