First Graphene just hit a major milestone. Working with their partner Breedon Group, the company produced about 600 tons of cement enhanced with graphene. This happened over a single day at a facility in the UK, and it’s a big deal because it shows this material can be made at a massive scale without slowing things down.

A Big Step for Greener Construction

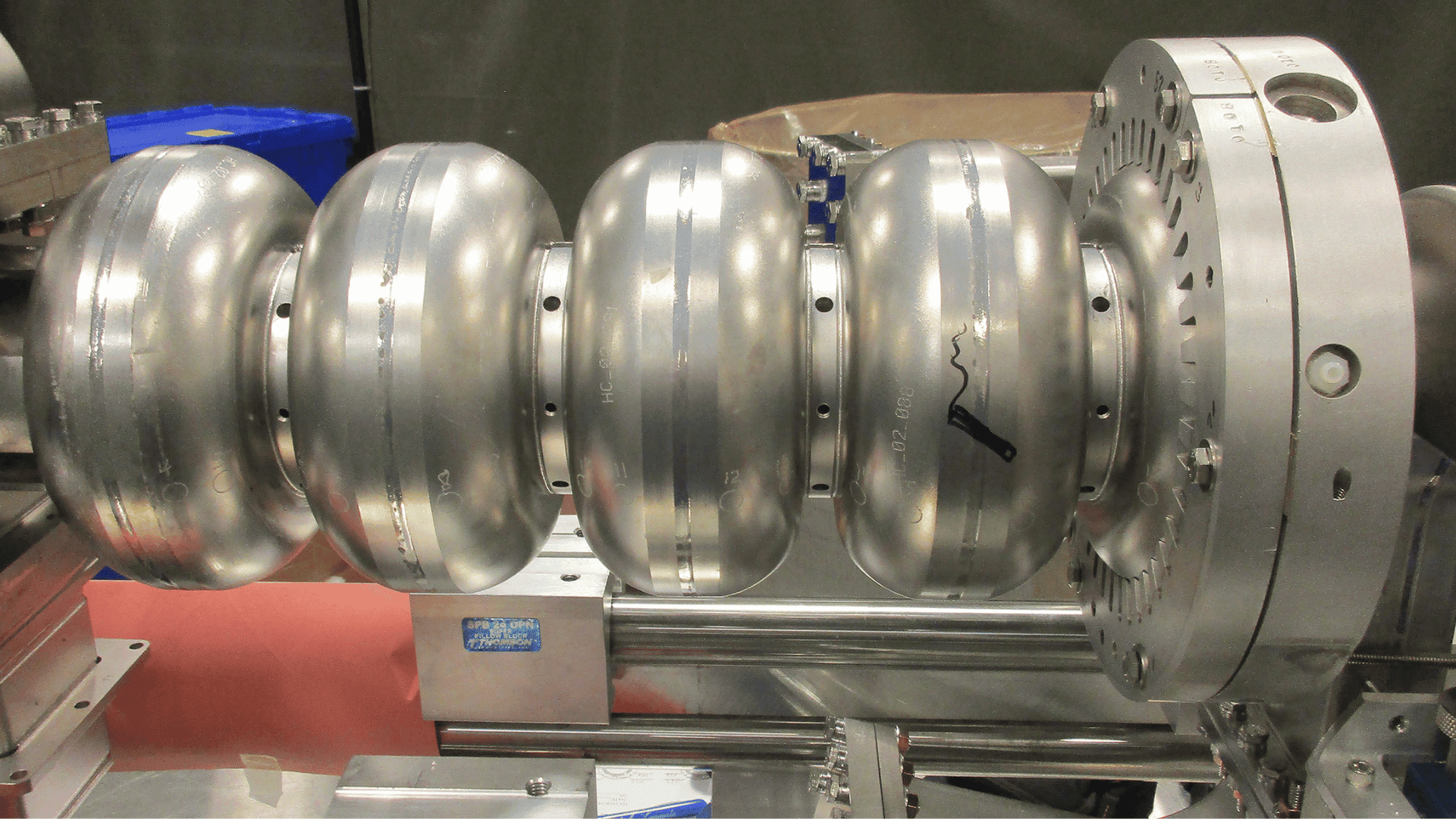

The team added about three tons of a graphene additive called PureGRAPH-CEM into the final milling stage of the cement. Adding graphene allows builders to use less “clinker,” which is the part of cement that creates the most carbon emissions. As a result, the new cement can reduce the CO2 footprint of a project by up to 16%.

Advertisement

For years, graphene was seen as a “lab material” that was too hard to use in the real world. This production run proves that’s not the case anymore. It’s a practical way to make construction a bit friendlier to the environment without reinventing the wheel.

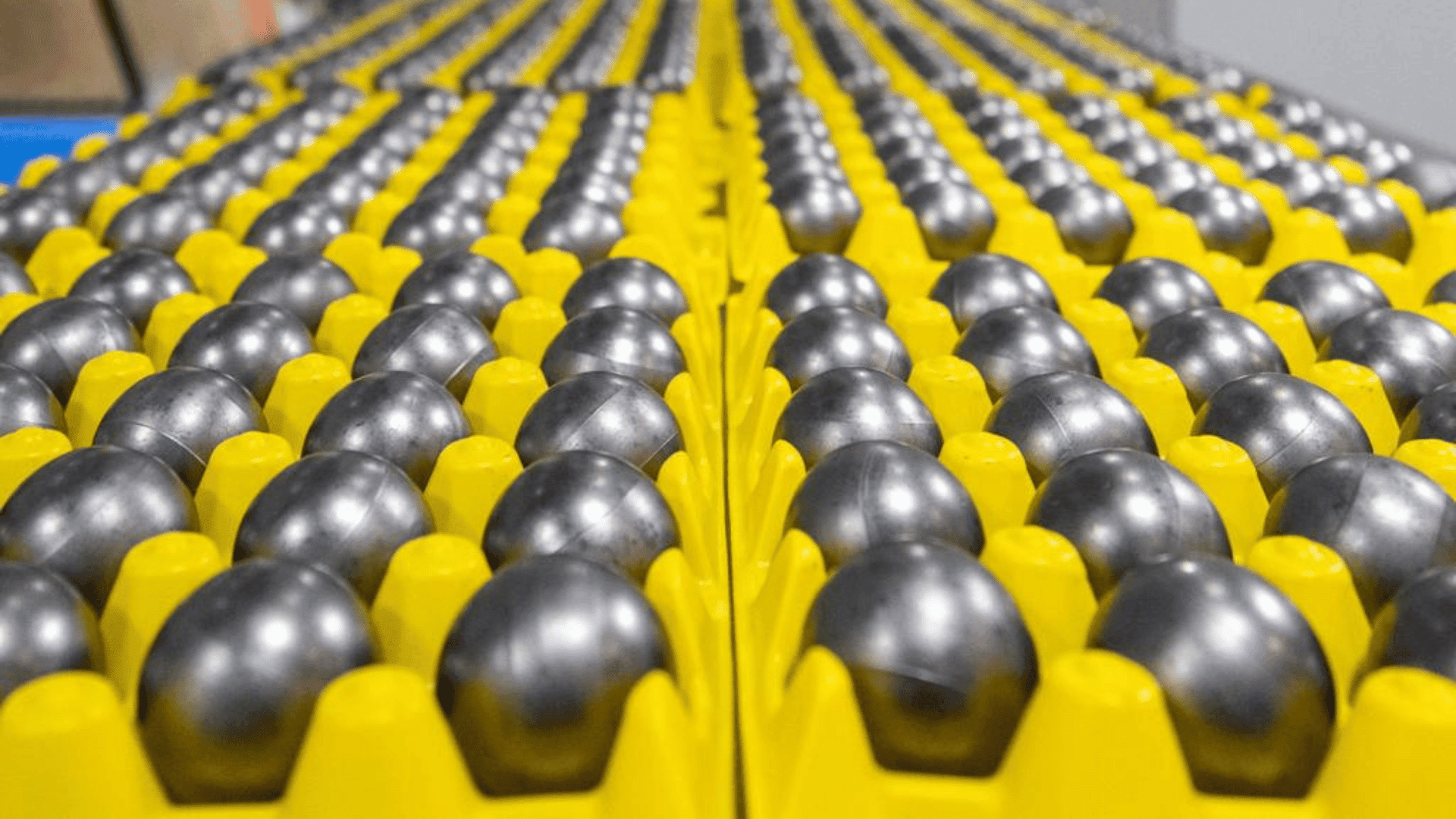

The 600 tons of cement aren’t just sitting around. They are being shipped out for a few different projects to see how the material holds up. Thousands of roof tiles are being made using this cement to see if they are stronger and if they help reduce waste. This is part of a plan to help build more affordable, sustainable housing.

The cement is also headed to two big infrastructure projects in the UK. At the same time, scientists at the University of Manchester will be running tests to see exactly how much stronger this concrete is compared to the regular stuff.

Michael Bell, the head of First Graphene, pointed out that this isn’t just a one-off experiment. The goal is to show that graphene can work for a lot of different things in the building world. Other companies in Australia and the UK are already asking for samples to run their own tests. It’s an optimistic moment for the industry. We aren’t just talking about greener building materials anymore—we are actually making them by the hundreds of tons.