For the past hundred years, making sneakers has been complicated. Factories far from the people who wear them glue together rubber, foam, leather, and fabric to create each pair.

This process is about putting parts together.

But this week, as the new “Atomic Green” colorways of the Nike Air Max 1000 hit the streets, we are witnessing the start of a new era. We are moving from the era of assembly to the era of growth.

Here’s why the Air Max 1000 is more than just a shoe: it’s a model for how products could be made in the future.

The “One Piece” Revolution

If you look closely at the shoes on your feet, you’ll notice seams, stitching, and glue. Most sneakers are made from many separate pieces. 3D printing pioneer Zellerfeld features zero parts. It is a single, continuous object.

The shoe is printed in one go using a special thermoplastic polyurethane called zellerFOAM. The real innovation is that the printer can adjust the density of the material as it prints.

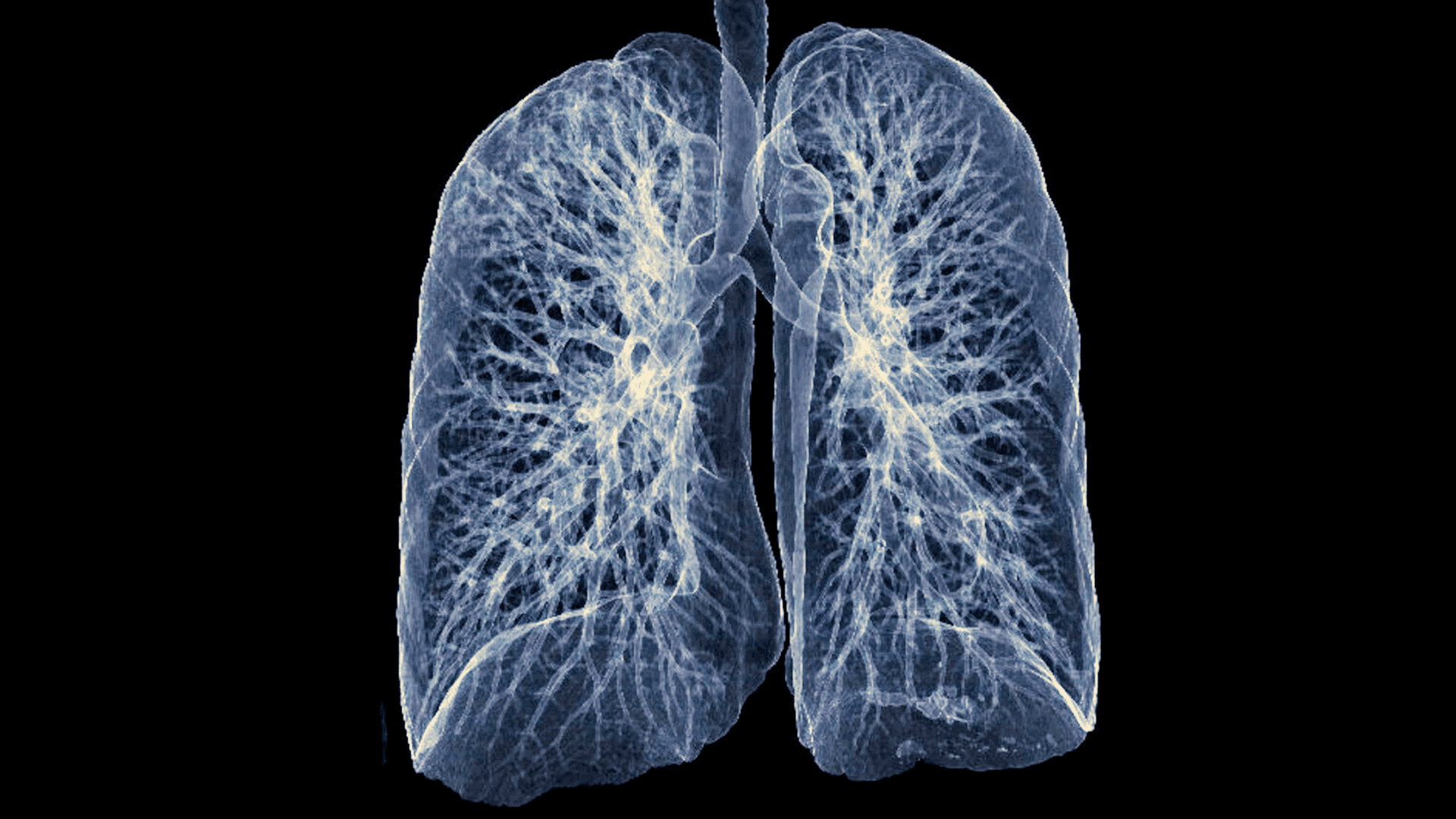

For the sole, the printer makes thick, sturdy parts to handle walking, while the upper is printed with thin, flexible patterns that let your foot breathe. It’s all the same material, just arranged differently, much like how human bone is tough outside and softer inside.

This is an example of biomimicry: utilizing one material in different ways, much like a bone, which is hard on the outside and spongy on the inside.

Solving the Recycling Problem

Advertisement

Making new things and being sustainable often don’t go together, especially with waste. Old sneakers are hard to recycle because you can’t easily separate the glue, leather, rubber, and foam. As a result, they end up in landfills.

Since the Air Max 1000 is made from one material, this problem goes away. When you’re finished with the shoe, you don’t have to take it apart. It can be ground up, melted, and turned into a new pair.

This is the ultimate goal of circular design, transforming old shoes into new ones repeatedly.

The Invisible Supply Chain

Perhaps the most futuristic aspect isn’t the shoe itself, but rather how it’s made and delivered.

Usually, raw materials are shipped to a factory in Asia, where shoes are assembled and then sent to the US or Europe.

With 3D printing, instead of shipping shoes, you just send digital files.

A factory doesn’t have to be huge anymore. It could be a small warehouse in Brooklyn, a center in London, or a shop in your local mall. In the future, shoes could be printed nearby, only when needed. That means no extra stock and no wasted shipping.

The Bigger Picture

The Air Max 1000 may look futuristic, but its real value is what you can’t see. It marks a change in how things are made.

Instead of sticking materials together with glue, we can now program materials to form the desired shapes.

The future of fashion won’t be sewn together; it will be printed.