The waiting list for organ transplants is long. About 100,000 people in the U.S. are currently waiting for an organ, and another 100,000 transplants happen every year. But the supply just doesn’t meet the demand.

A team led by Carnegie Mellon University (CMU) is trying to fix this math. They recently received an award of up to $28.5 million from the Advanced Research Projects Agency for Health (ARPA-H) to try something ambitious by 3D printing a human liver.

Letting the Body Heal

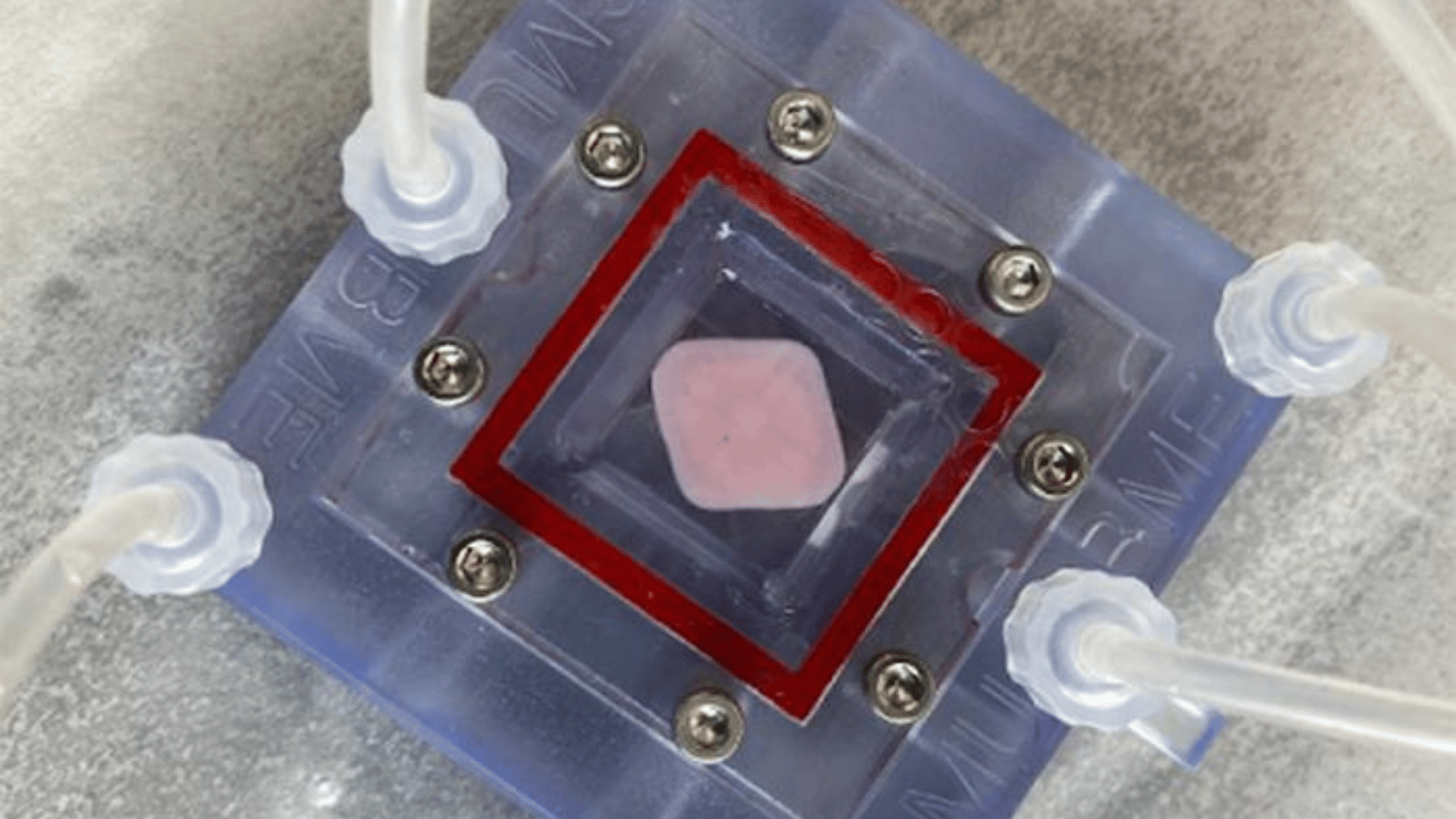

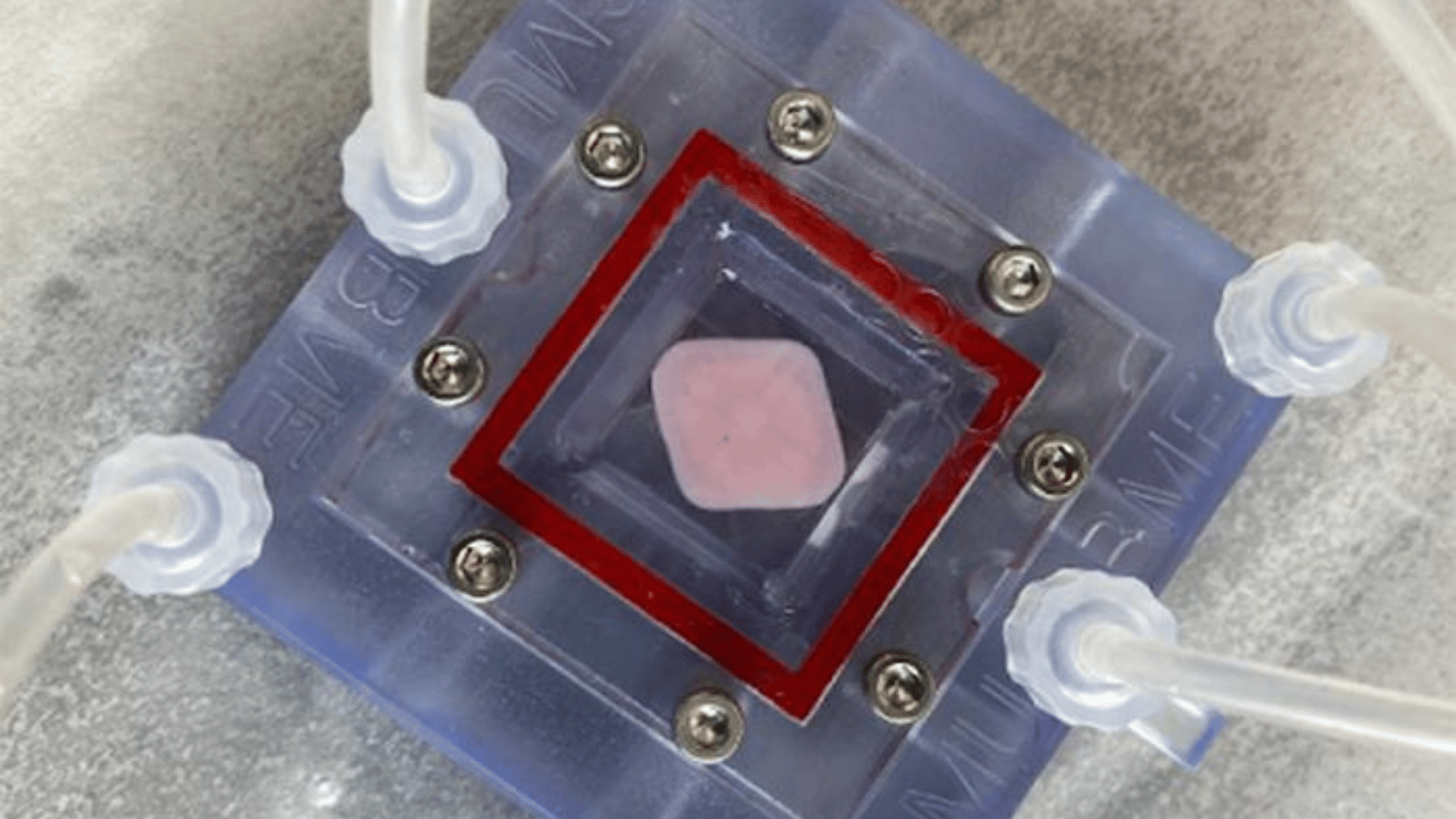

The project is called LIVE (Liver Immunocompetent Volumetric Engineering). The idea isn’t necessarily to give someone a printed liver forever. Instead, it’s about creating a bridge. The team wants to print a functional liver that supports a patient with acute liver failure for a short time.

“The goal is to create a piece of liver tissue that you can use as an alternative to transplant, specifically for acute liver failure,” said Adam Feinberg, professor of biomedical engineering at Carnegie Mellon and principal investigator.

This is how it would work: The printed liver acts as a backup generator and supports the patient for a few weeks.

Advertisement

“The liver we are creating would last for about two to four weeks. It would give patients time for their own liver to regenerate, and then, they would not need a liver transplant, freeing up those livers for other patients,” Feinberg said.

If the patient’s own liver heals during that window, they come off the transplant list. That saves them from a major surgery and saves the donor organ for someone who needs a permanent replacement.

3D Printing a Liver Without Rejection

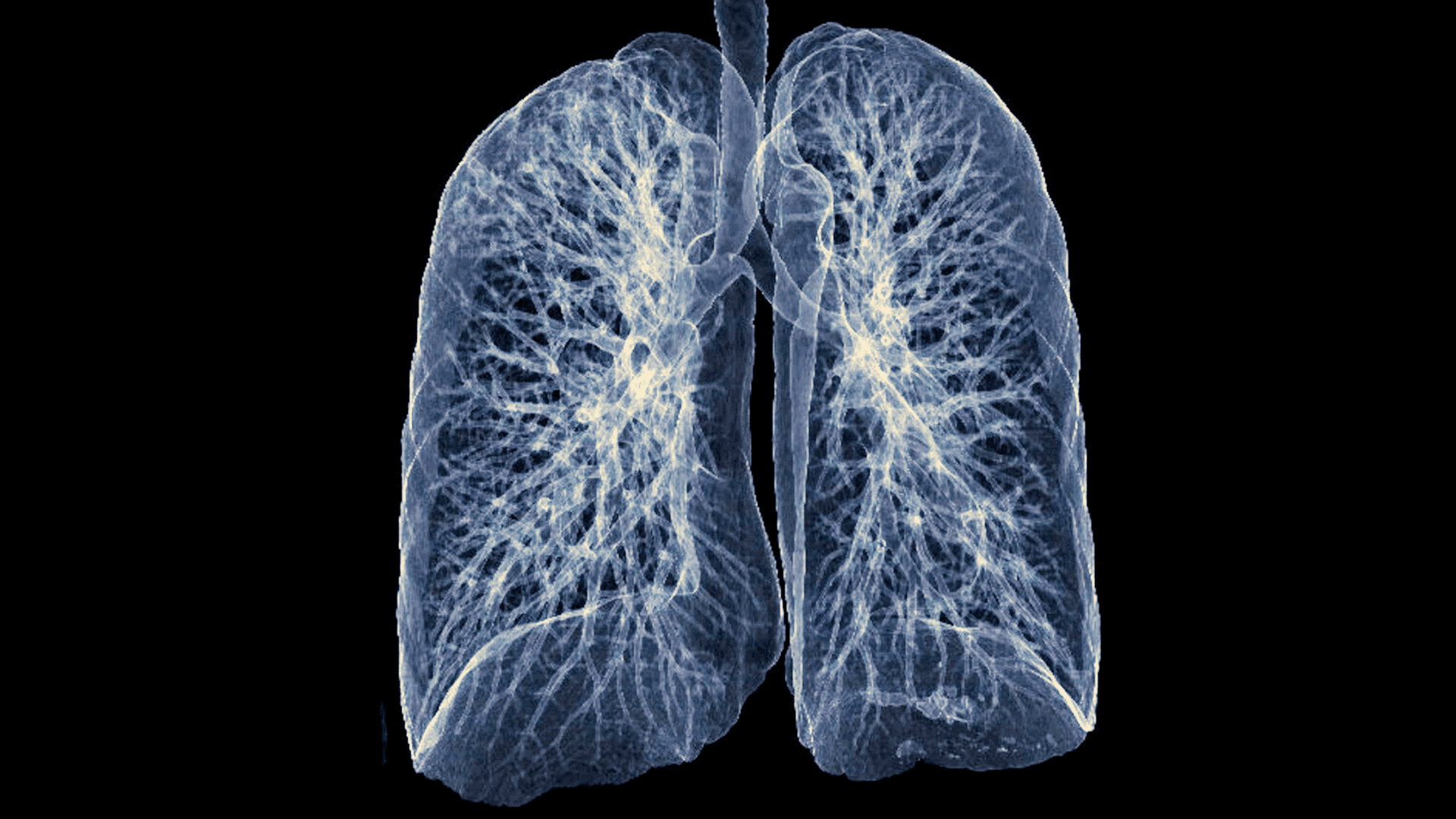

Printing an organ is complicated. The team, which includes experts from the University of Washington, Mayo Clinic, and others, uses CMU’s FRESH 3D bioprinting method. They build the liver using real human cells and structural proteins like collagen.