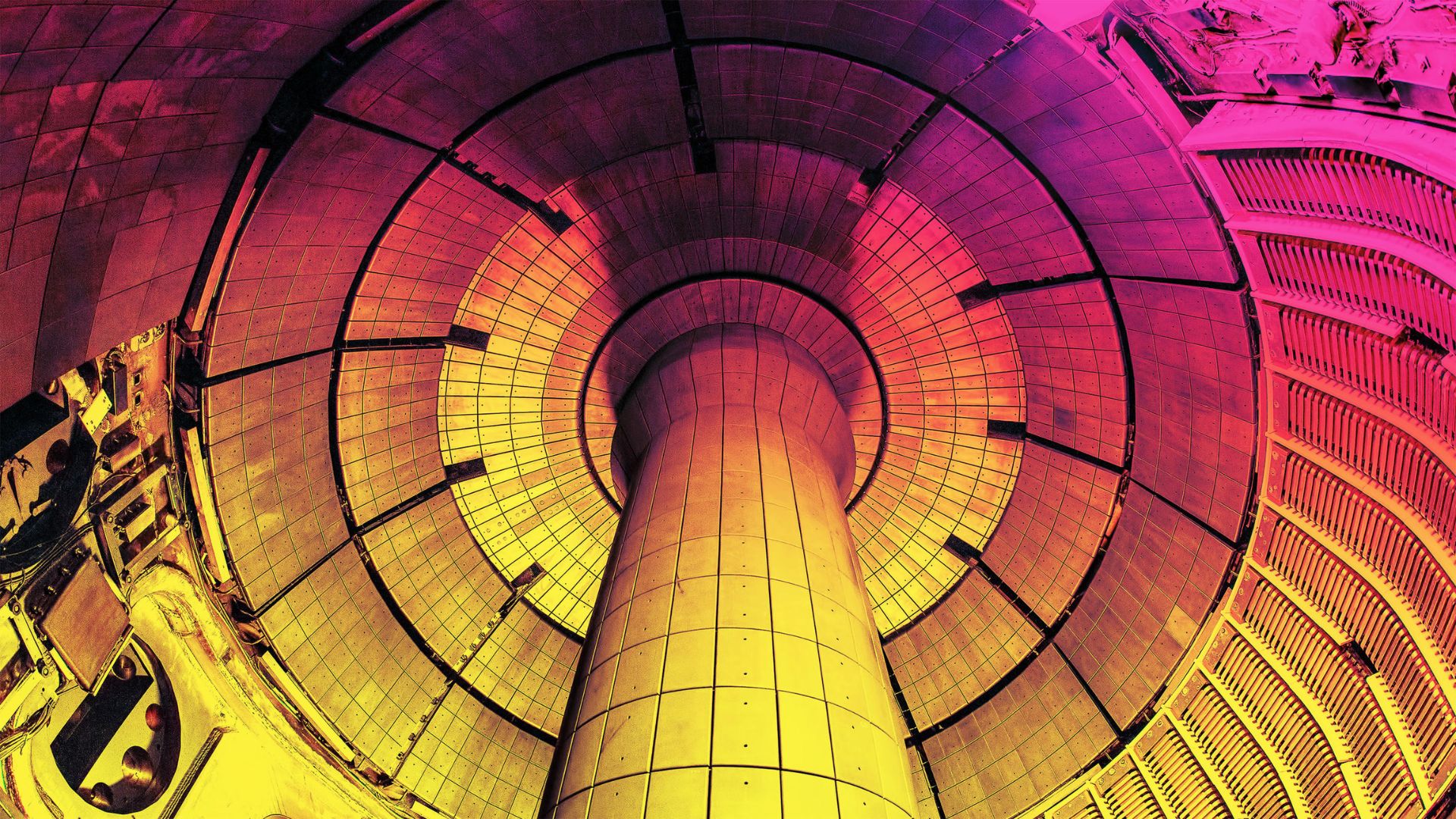

Nature often utilizes complex mathematical geometries. Researchers at the Idaho National Laboratory (INL) are harnessing similar natural phenomena to redesign nuclear reactor fuel. Researchers are taking control of the minimal surface, the phenomenon where shapes achieve the smallest possible surface area within a given boundary.

This geometry is observed throughout the biological world, from the wings of butterflies to the membranes of mitochondria. Specifically, INL researchers are exploring Triply Periodic Minimal Surfaces (TPMS). These surfaces form an intricate, repeating, 3D lattice structure.

A New Design For Nuclear Fuel

Researchers call their new design INLFUX (Intertwined Nuclear Fuel Lattice for Uprated heat eXchange). According to the scientists, INFLUX seeks to improve transfer compared to conventional cylindrical fuel rods. INL researcher Nicolas Woolstenhulme says the cylindrical rods are based on 1950s heat exchanger designs, which he considers “a terrible shape for heat transfer.”

INFLUX fuel apparently “trades” the simple cylinder for the complex TPMS lattice. As a result, it forces the coolant to follow a “smooth labyrinth” path. The route, which is longer than usual, ensures superior mixing and dramatically enhances the transfer of heat from the fuel to the coolant.

Woolstenhulme said, “It’s nature’s answer to the optimal geometry for nuclear fuel.”

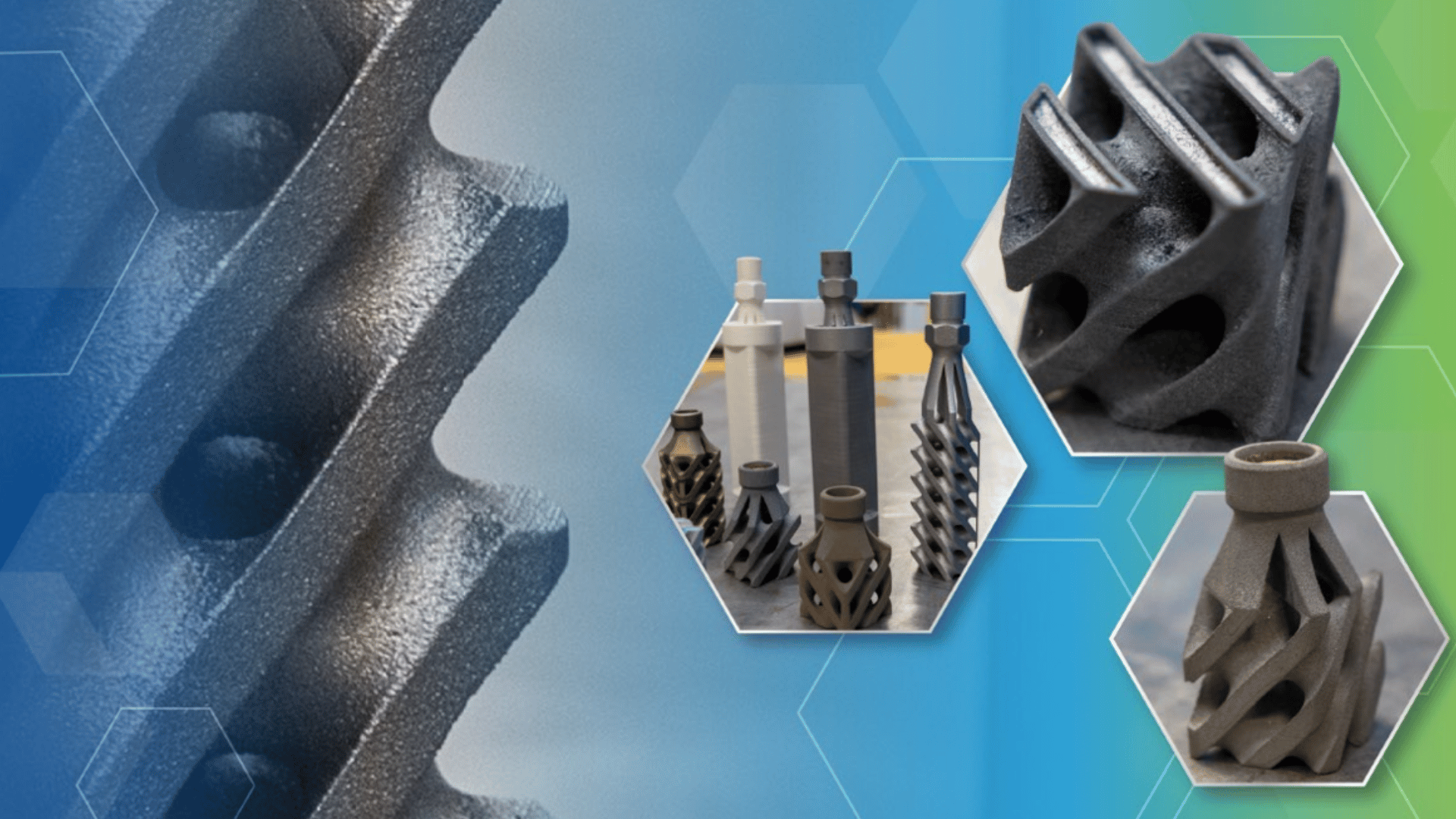

Woolstenhulme and his team, which included Professor Mark Anderson, tested this concept using 3D printing to create an electrically heated polymer-composite version of the INFLUX lattice. Researchers say the results demonstrated a profound impact of the new geometry.

“The bottom line is that this geometry does indeed triple the heat transfer coefficient compared to standard rod-type fuel,” said Woolstenhulme. “That’s a big deal. It has a direct impact on the power density of the fuel rod and thus the economics of a nuclear reactor.”

Additionally, computer modeling suggests the INFLUX design reduces the nuclear fuel’s thickness and temperature. The continuous lattice aids cooling, which could improve reactor safety and resilience.

Ultimately, the research has proven the core hypothesis that a TPMS shape can create a more efficient and compact nuclear reactor core.