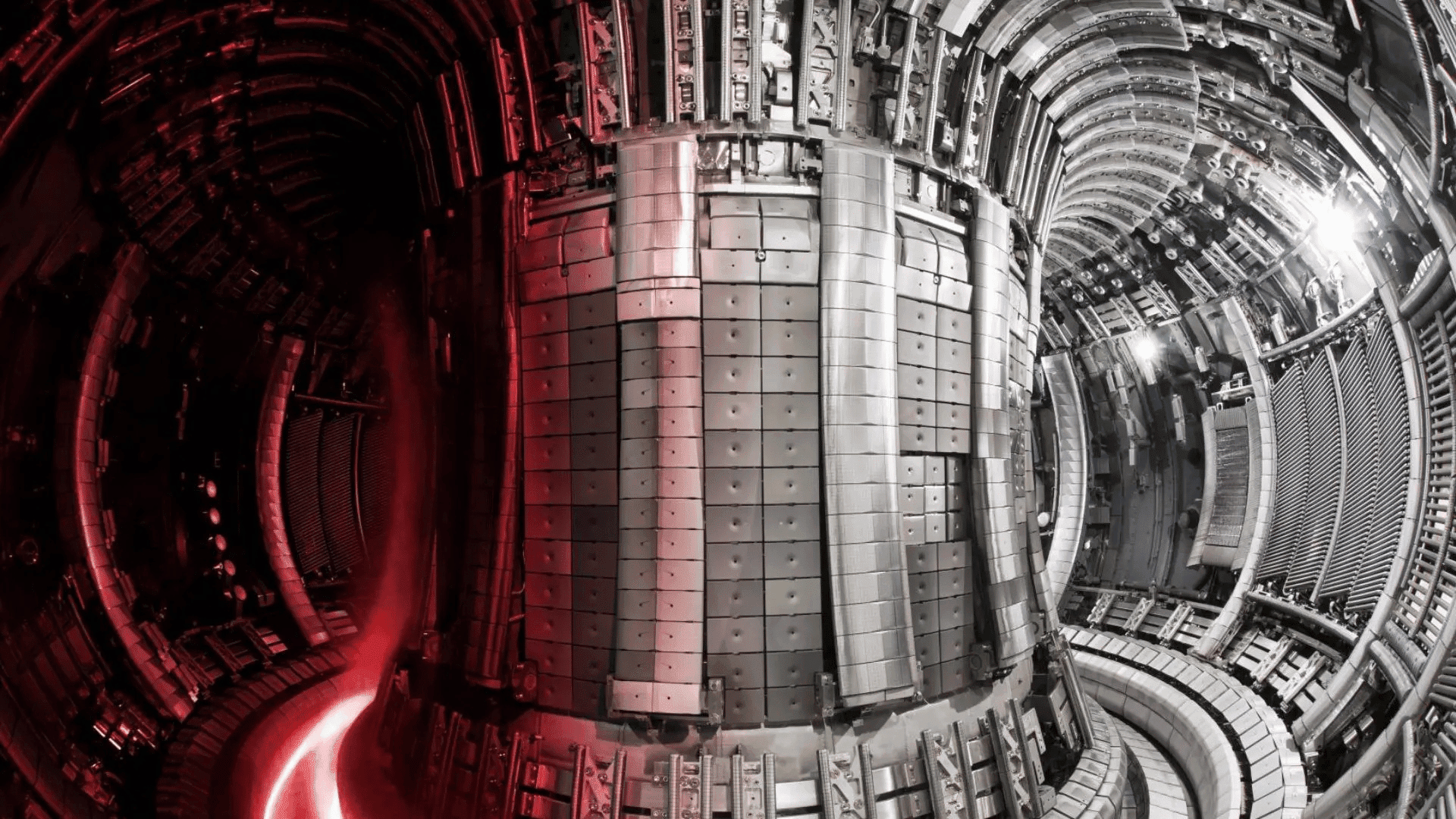

Making fusion possible on Earth is essentially trying to build a star on our planet. It’s no easy feat, but engineers in Nottinghamshire cleared a major hurdle. The team at STEP (Spherical Tokamak for Energy Production) is working on a prototype fusion plant at West Burton with the goal of putting electricity on the grid by the 2040s. To get there, they have to figure out how to manage the massive, powerful magnets that keep fusion fuel in place.

The Plug-and-Socket Solution

Usually, fusion magnets are built as solid, permanent pieces. If something goes wrong or needs a tune-up, the repairs are slow and incredibly expensive. It’s like having a car where the engine is welded shut. To fix this, STEP engineers are developing “remountable joints.” Think of these as industrial-scale plugs and sockets. They allow sections of a magnet to be taken apart and put back together for maintenance.

By making the magnets easy to take apart, the plant can have shorter shutdowns and lower costs over its lifetime. The team even came up with a clever way to keep these joints tight. They created a clamping system using a sealed bladder filled with liquid. As the liquid freezes during the cooling process, it expands and creates even pressure across the connection. It is a simple, effective way to handle the extreme forces inside a fusion reactor.

Moving Toward the Grid

The team is looking at how to actually build these things at scale. Studies show these joints can be made using several different industrial techniques, which means the UK supply chain can handle the workload. Right now, more testing is happening to see how multiple joints work together in a real-world setting.

“The ongoing realisation of STEP’s RMJ technology is a multi-million-pound project. But what’s notable is we’ve gone from a concept sketch to delivering and shipping a product for testing in one financial year,” Aurobindo Siddarth Swaminathan, the lead engineer for magnets at STEP, said.

“This has only been possible through successful collaboration with industry partners, the UK Atomic Energy Authority (UKAEA) as the fusion partner, and UK Industrial Fusion Solutions (UKIFS) – bringing their combined expertise to the STEP program.”