S4E16 – Cyber Security: Thinking Like An Attacker

George sends Tamara to the World of Innovation to explore how advances in cyber security are defending us against hackers.

George sends David to the World of Innovation to explore the technology—and sustainability—behind tire manufacturing.

George sends Tamara to the World of Innovation to explore how advances in cyber security are defending us against hackers.

George sends Greg to the World of Production to explore how the design and application of new materials is changing the way we build.

George sends Darieth to the World of Innovation to explore the ways humans can get better nutrient absorption and how technologies inspired by nature are benefiting the supplements we take today.

George sends Greg to the World of Innovation to explore how digitized cash back programs are helping shoppers save with every trip to the grocery store.

In the final part of our four-part exploration, Greg explores how Nuclear Energy is helping with space exploration and George leads a roundtable talk with some of nuclear energy’s top minds to discuss what nuclear energy looks like in tomorrow’s world.

In part three of this four-part exploration, George sends Greg to explore how Small Modular Reactors can help provide power to remote locations or during natural or other major outages.

In part two of this four-part exploration, George sends Greg to discover the history of nuclear energy, how nuclear energy is being used in today’s world, and what tomorrow’s nuclear reactors might look like.

In part one of this four-part exploration, George sends Greg to the field to discover how Nuclear Energy is helping us reach our goal of a zero-carbon footprint by 2050.

In the World of Production, George sends David to explore how ductile iron pipes are made and discovers how innovating a small part of an invention that has been around for centuries can make a huge difference in our infrastructure.

As the demand for real estate increases, George dives deeper into the World of Innovation and sends Darieth to explore the latest technological advances that are revolutionizing the industry for both consumers and for agents.

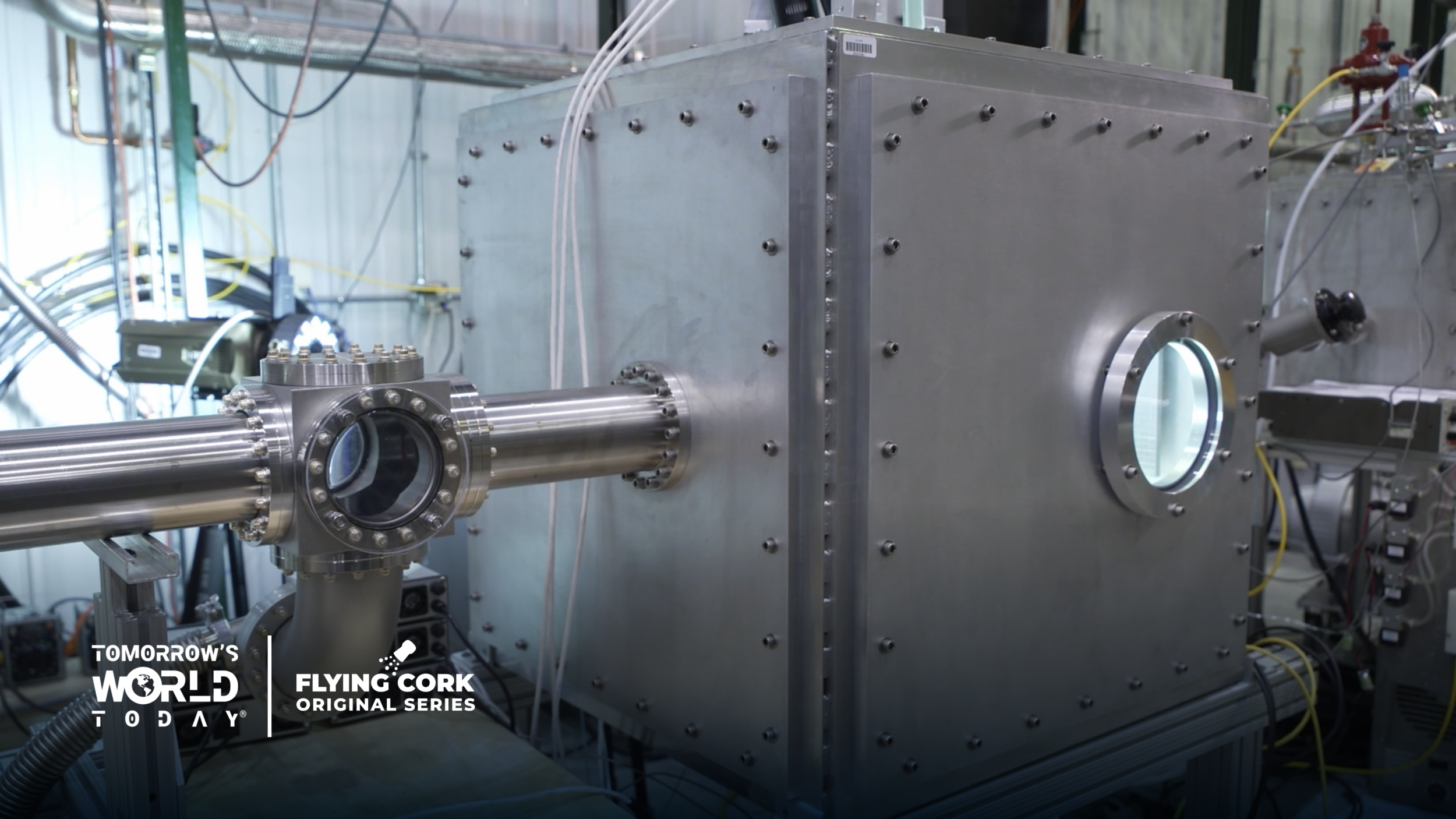

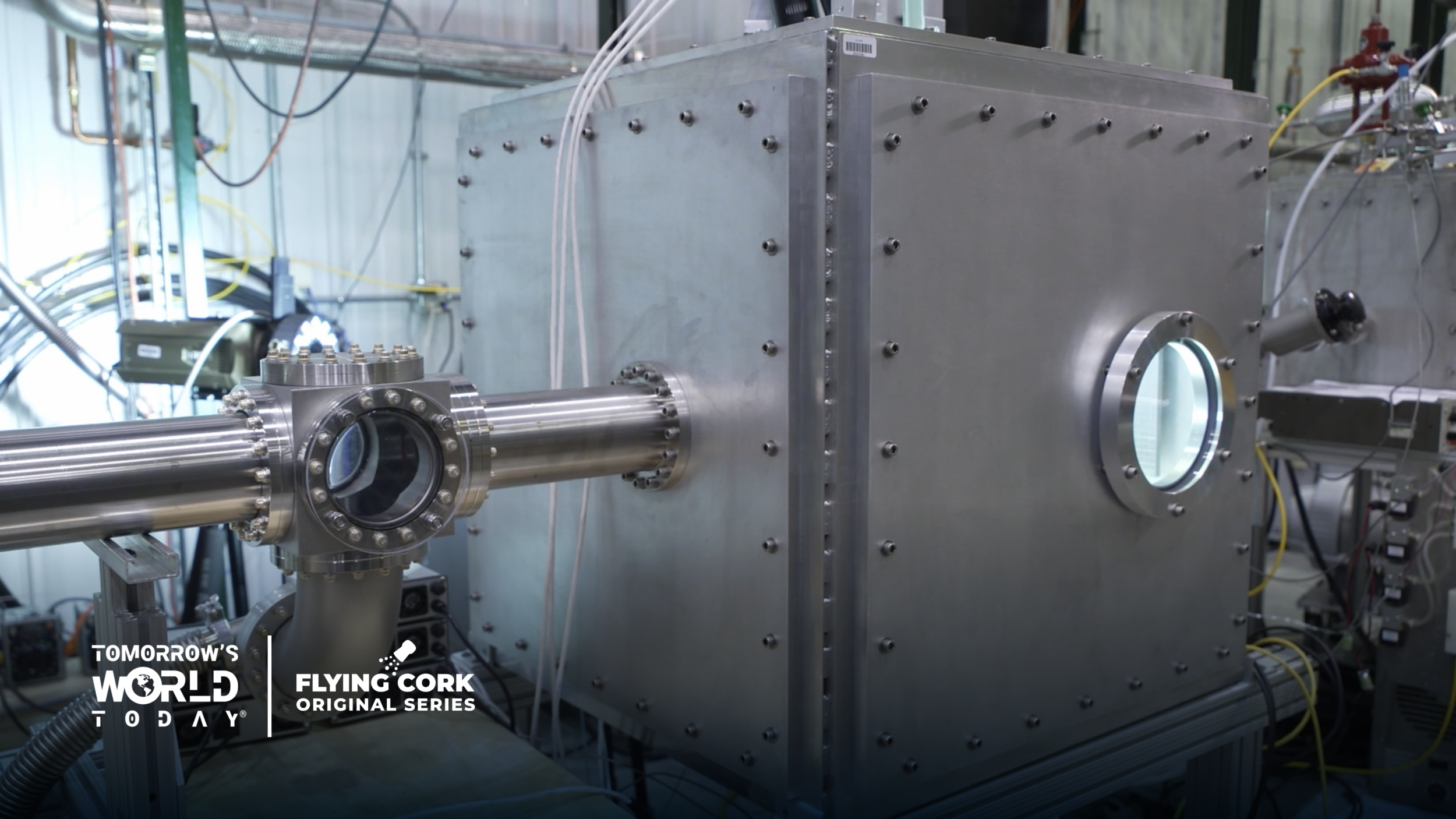

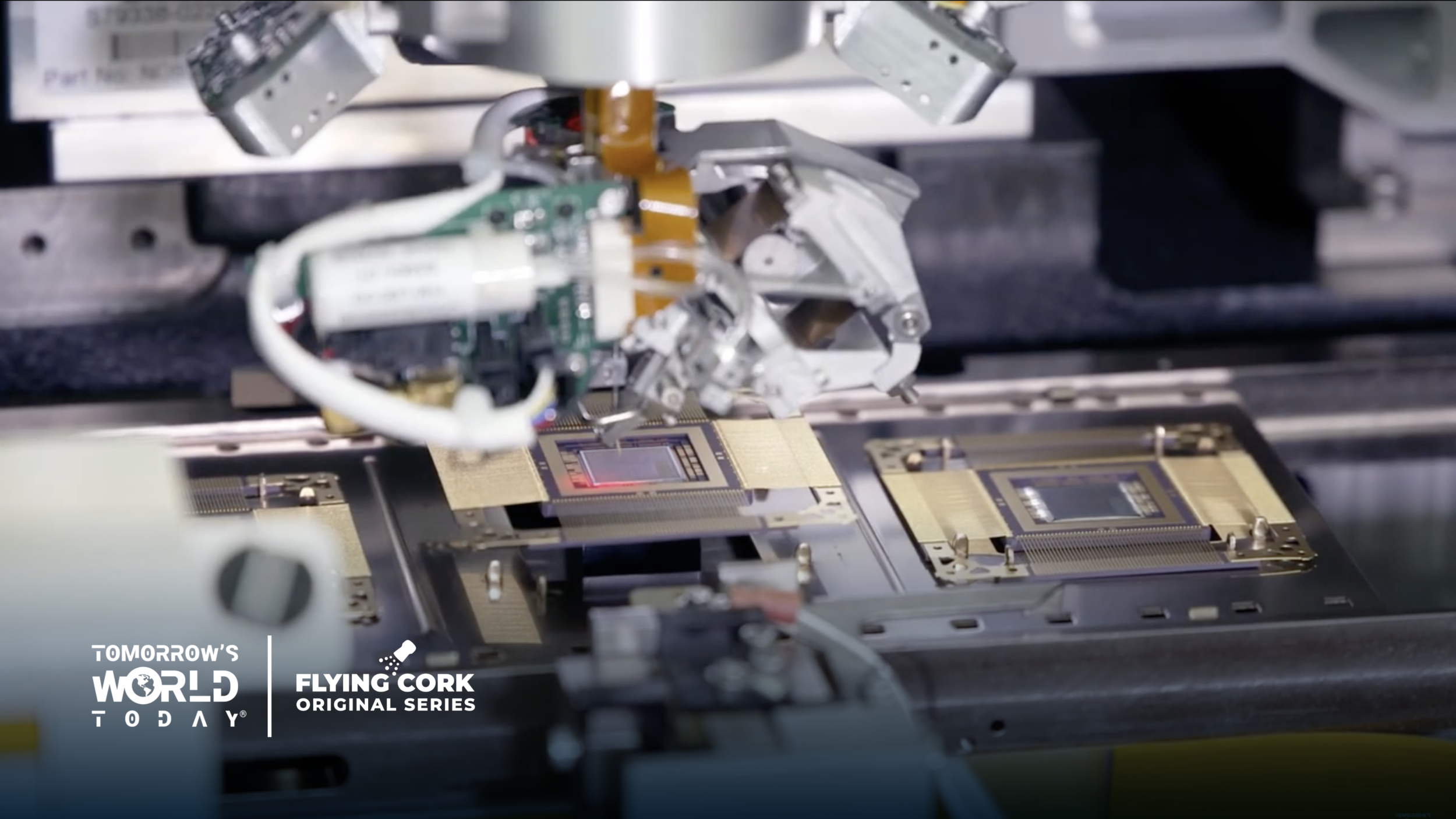

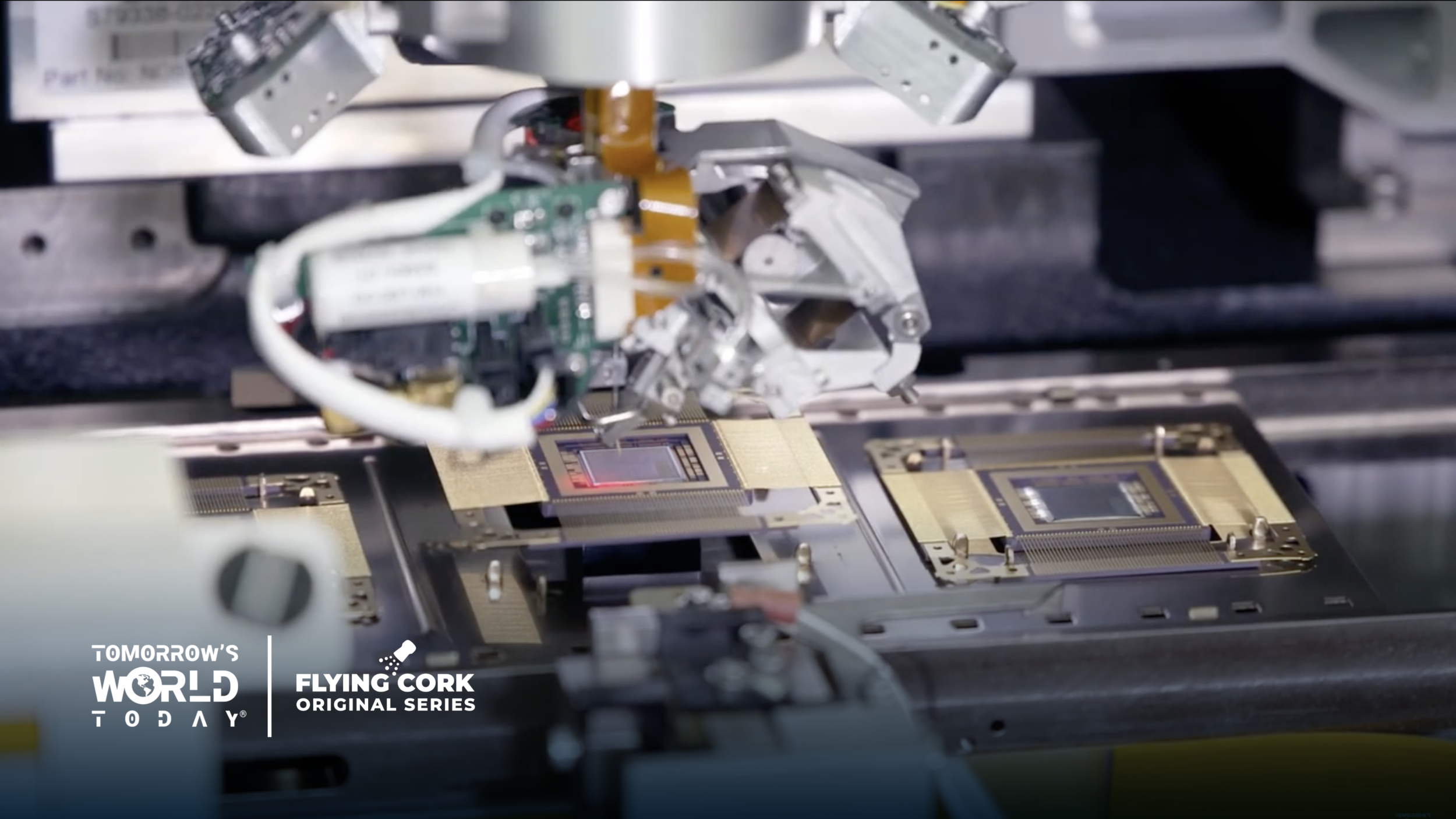

In the World of Production, we explore making semiconductors that can work in space and discover how one company is taking a bite out of wafer production by mimicking space’s atmosphere right here on Earth.

You may have seen autonomous cars driving on the road, but did you know that autonomous mining vehicles have been around for decades? We visit the World of Production to explore the past, present, and future of autonomous mining.

In the World of Production, we explore how one company is helping to salvage trees after wildfires and how forestry management helps keep our forests healthy.

In the World of Innovation, we discover how compressed air—and a math equation from the 1700s—are being used in modern manufacturing. Our field reporter Greg brushes up on his ABCs, and we celebrate the first ever National Pneumatics Day.

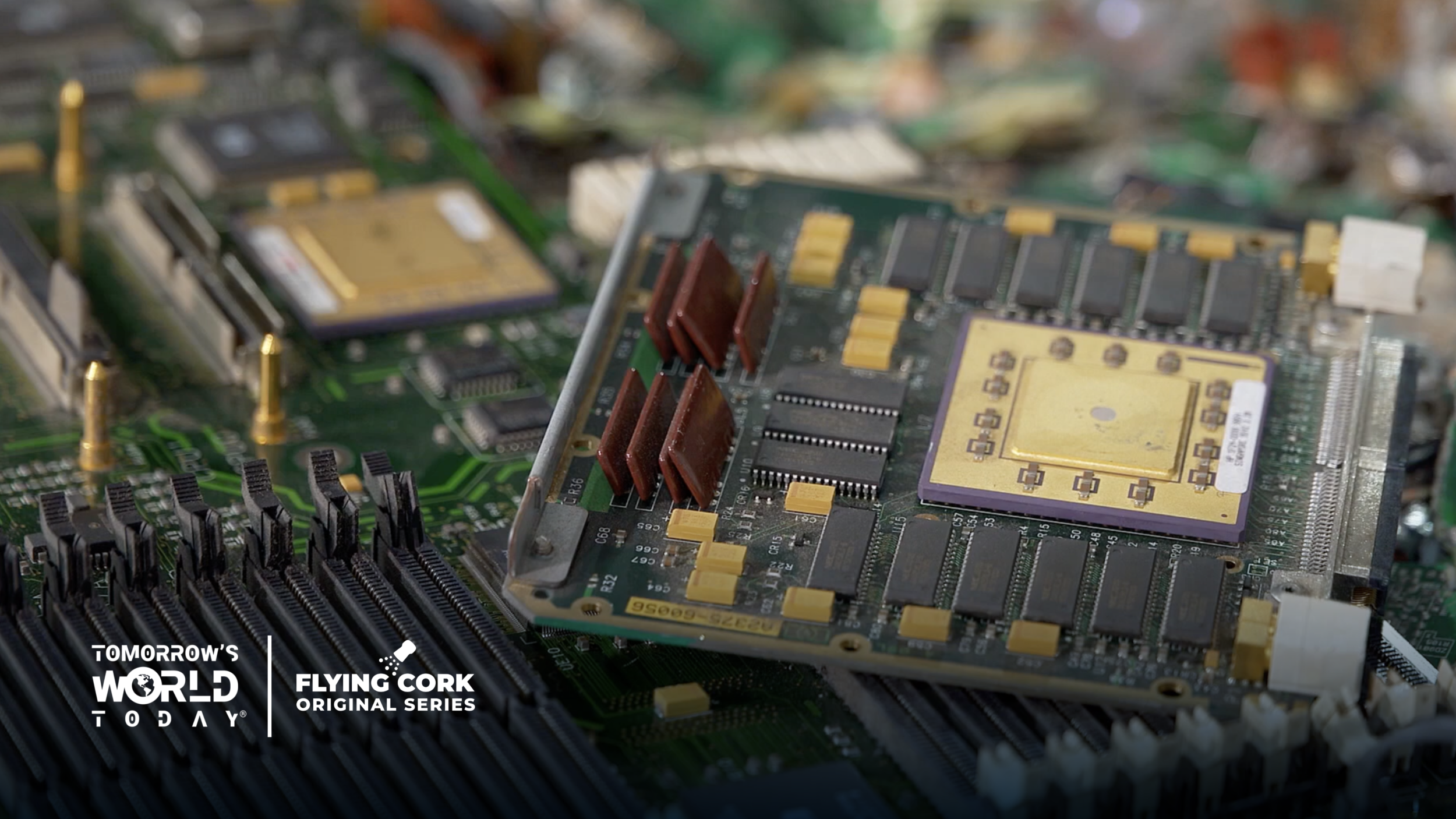

In the World of Innovation, we learn how mining has evolved from the days of the California Gold Rush to harvesting the precious metals found inside our electronic scrap and how electronics recycling helps our environment.