Liquor can come in a variety of colors from golden to deep brown to even clear, but how do we make the process of creating liquor more green? In this episode of Tomorrow’s World Today, correspondent Darieth visited Bulleit distillery headquarters to learn about the history behind their bourbon, their distilling process, and their innovative efforts to make their manufacturing more sustainable.

Research done by the Beverage Industry Environmental Roundtable (BIER) found that on average a 750-milliliter bottle of liquor produces 6.5 pounds of carbon dioxide. Distilleries can also use a lot of water, producing on average 12 times as much wastewater as the amount of alcohol produced. This can average out to be roughly eight to fifteen liters of waste materials per liter of alcohol produced. Given the environmental impact they can have, many distilleries are working to make their processes more sustainable.

Distillation

According to the BIER report, the distillation process is the number one contributor to a spirit’s carbon footprint. The distillation process requires a lot of power as well as produces a lot of waste including wastewater, spent mash, and liquor specific goop (Ex. Tequila’s pulp). Efforts by distilleries and brands have focused on reducing waste and finding ways to recycle what waste they do produce.

Although it is an outlier, one way distillers have found recently to reuse some of their waste is to recycle it to make hand sanitizer. Not only did many distilleries work to fill the supply when it was at its lowest at the beginning of the pandemic, but many give theirs to charity or give away a bottle with each purchase. This prevents the waste from ending up being made into a fertilizer where it can have harmful environmental effects or sending it to be treated which is very difficult and expensive for this particular type of waste.

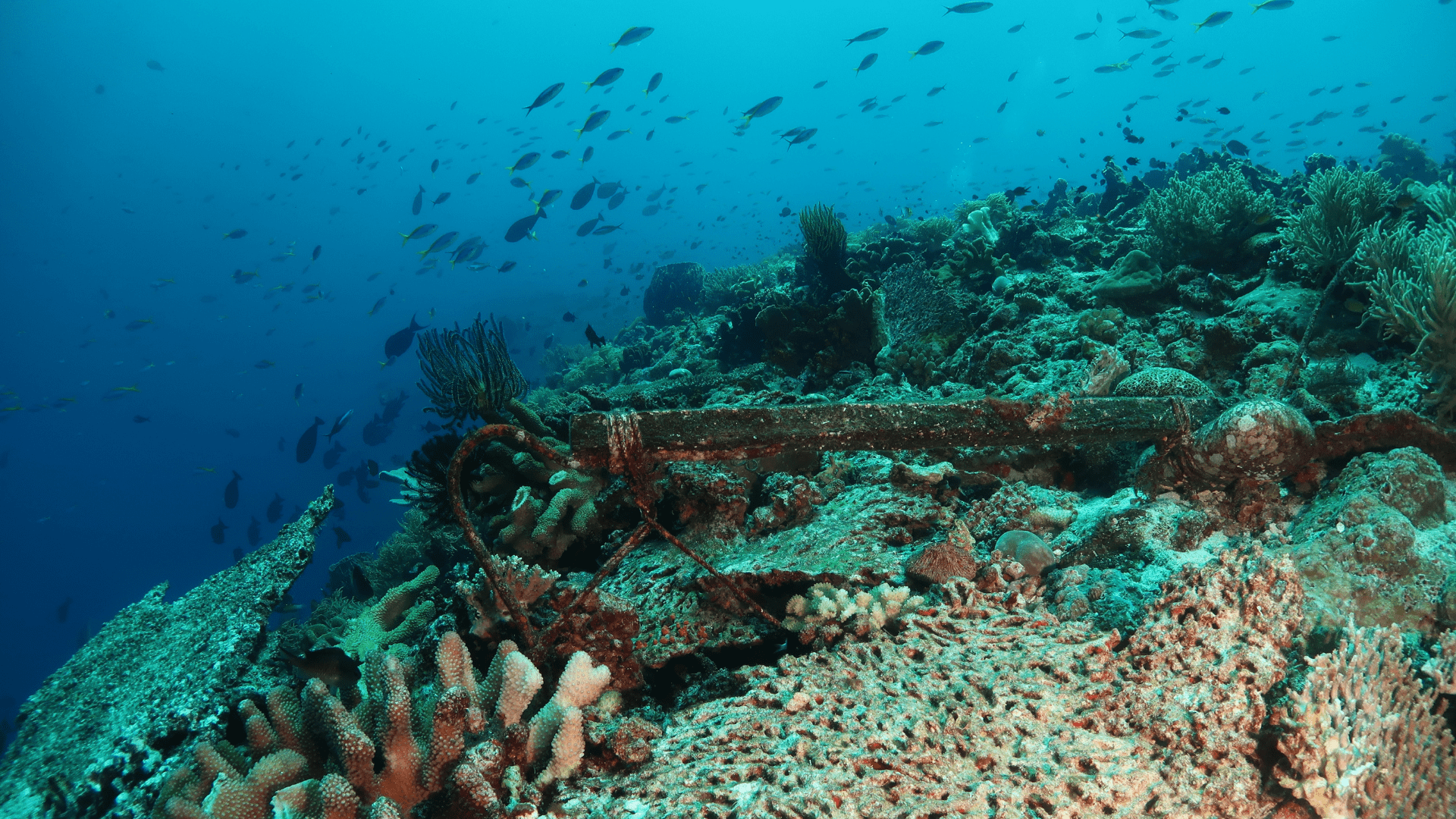

Many whiskey distilleries are reducing waste by converting spent grain into animal feed. One company, New York’s Five & 20 Spirits Brewing, has a unique process by which their spent grain and wastewater is converted into edible biomass ‘fish food’. The food is then pumped into onsite growth tanks for their local partner, Timberfish Technologies, which farms Atlantic salmon, speckled trout, and shrimp. Some distillers have even partnered with bakeries in upcycling ventures in order to repurpose their spent grains into ingredients for baked goods.

Energy

Another way that distilleries are becoming more sustainable is through energy conservation efforts. The liquor giant Bacardi Limited, for example, has a process by which they can convert their waste into energy using an anaerobic digester system to produce methane. According to Food Print, a 2018 life cycle study of Scottish malt whiskey showed that energy costs can be reduced by 15% when distillation by-products are converted into renewable energy through the production of biogas.

Some distilleries have also taken advantage of cold climates and resources to help reduce the energy needed for chillers. Montanya distillers, for example, produces their rum at a high altitude distillery which contains water cold enough to be used for their cooling processes.

Packaging

According to the BIER report, packaging accounts for roughly 20 percent of a distillery’s carbon footprint. So many different materials go into making liquor packaging. What mainly comes to mind is their container, being in a glass or can, but there’s also the label, glue, cork, and the boxes used to transport the liquor to stores around the world. All of these together can significantly impact a company’s carbon footprint.

Some companies are finding innovative ways to decrease their carbon footprint in the area of packaging. For example, according to Grist, Greenbar Distillery has begun to use a lighter form of glass for their liquor, 35 percent post-consumer waste cardboard, 100 percent post-consumer waste recycled paper labels, and soy-based inks. Through these efforts, the company has managed to reduce its carbon footprint between 1.88-4.04 pounds of CO2 per 750-milliliter bottle (depending on the line). The typical amount for North American liquors is 6.30 pounds of CO2 per 750-milliliter bottle according to the BIER report.

Other companies have managed to reduce their environmental impact by finding locally sourced glass bottles, which saves greenhouse gas emissions as opposed to having them shipped overseas. Bacardi has recently begun an initiative to create a biodegradable bottle by 2023 while Diageo is primed to launch their plastic-free bottles in 2021, made from sustainably sourced wood pulp.